Undoubtedly, when it comes to electronic system design, most people focus on integrated circuits, while the accompanying passive components often go unnoticed. However, the value of passive components should not be underestimated.

To ensure that the expected performance requirements are met at the time of delivery, and that the end equipment possesses all necessary functions, passive components integrated into electronic hardware play a crucial role. If a specific component—no matter how small or inexpensive it is—cannot be procured within an acceptable timeframe, it may have a significant impact on the production process of the OEM (Original Equipment Manufacturer). Existing orders may fail to be completed, ultimately missing potential opportunities.

The past year and a half has been the most challenging period in the history of the global electronics supply chain. Production disruptions caused by the COVID-19 pandemic have exacerbated the already emerging component shortages.

Even before the outbreak of COVID-19, the supply of multilayer ceramic capacitors (MLCC) was limited due to long lead times. Demand had been sluggish through the end of 2018 and early 2019, causing many manufacturers to significantly reduce MLCC production capacity. However, since then, market dynamics have revived demand for these components, which has now reached unprecedented heights.

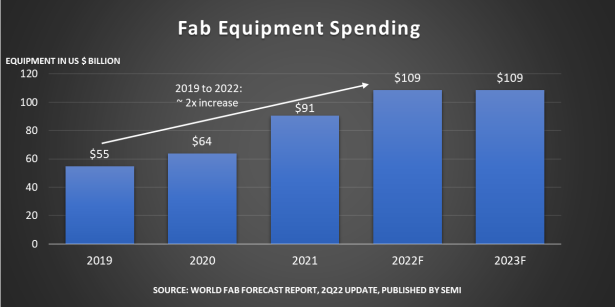

According to a report from Mordor Intelligence, the global MLCC market value reached $10.3 billion in 2020 and is projected to exceed $15 billion by 2026. During this period, the compound annual growth rate (CAGR) of MLCC will be 5.42%. Industries driving MLCC demand include 5G smartphones, electric vehicle (EV) powertrains, and renewable energy generation systems.

Electric Vehicles and Applications In the coming years, the number of electric vehicles (EVs) on the roads will increase significantly, helping society reduce carbon emissions (related to climate change) and nitrogen oxide emissions (which harm human health). If predictions by the International Energy Agency (IEA) are correct, by 2030, the number of registered electric vehicles will exceed 145 million. With the widespread adoption of charging infrastructure, charging times for EV batteries will also shorten.

At the same time, increasing the voltage of EV powertrains will help improve power, thereby extending the range of the vehicle on a single charge. Although these innovations will help increase the adoption of EVs, the high voltage required will place additional loads on related circuits, necessitating the use of more passive components. Currently, each electric vehicle requires over 10,000 MLCCs, underscoring the massive total demand for MLCCs in the market.

5G Mobile Communications To achieve the higher data rates and greater data volumes promised by 5G networks, 5G communication will not only require more stable frequencies but will also use higher frequency bands, particularly in the millimeter-wave region of the radio frequency spectrum. As a result, there will be an increasing demand for higher-value capacitors and lower-loss magnetic components.

Internet of Things Infrastructure In the coming years, billions of IoT nodes will be deployed to support industrial automation and smart city solutions. This will drive demand for supercapacitors, which can be used for energy harvesting—to store energy gathered from the surrounding environment by devices such as photovoltaic cells and thermoelectric generators (TEGs). This means that the need to replace batteries—an expensive and logistically challenging task—will be eliminated.

Redefining the Passive Component Supply Chain Facing the current shortage of available stock, OEM manufacturers are under immense pressure. They need to find ways to alleviate the supply shortages and shorten lead times for related components. To achieve this, OEMs must work more closely with distributor partners.

Looking ahead, the "just-in-time production" culture established in the past decade will no longer be applicable. Instead, engineering and procurement departments within OEMs need to be better prepared to avoid the risk of needing to redesign products due to insufficient components—and the potential financial losses resulting from this.

If OEMs have a clearer understanding of mid- and long-term demand for passive components, they can plan more effectively in advance. Additionally, negotiating with their preferred distributors will allow them to stay informed of current industry trends and any potential demand hotspots that could negatively impact the supply of specific components.

On the other hand, distributors must leverage their knowledge of the market and key applications to determine where demand may be most urgent. This way, they can ensure their component inventories meet customer needs. If a component is difficult to source, they must use their expertise to suggest potential alternatives.

The electronics industry is constantly evolving, keeping up with the times and never standing still. Exciting new applications are emerging, requiring the selection of appropriate components to support these applications.

Although most processes focus on high-end active components, the procurement issues surrounding passive components are often the most prominent. The recent shortage of MLCCs faced by OEMs only underscores this point. It also highlights the importance of establishing effective supply channels to address bottlenecks in the component supply chain.